LiBER proposal relies on the following key technologies:

Container made of composite materials

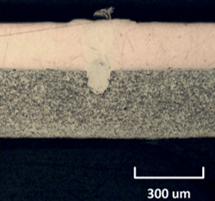

Electrical insulation

Passive safety

Post crash safety

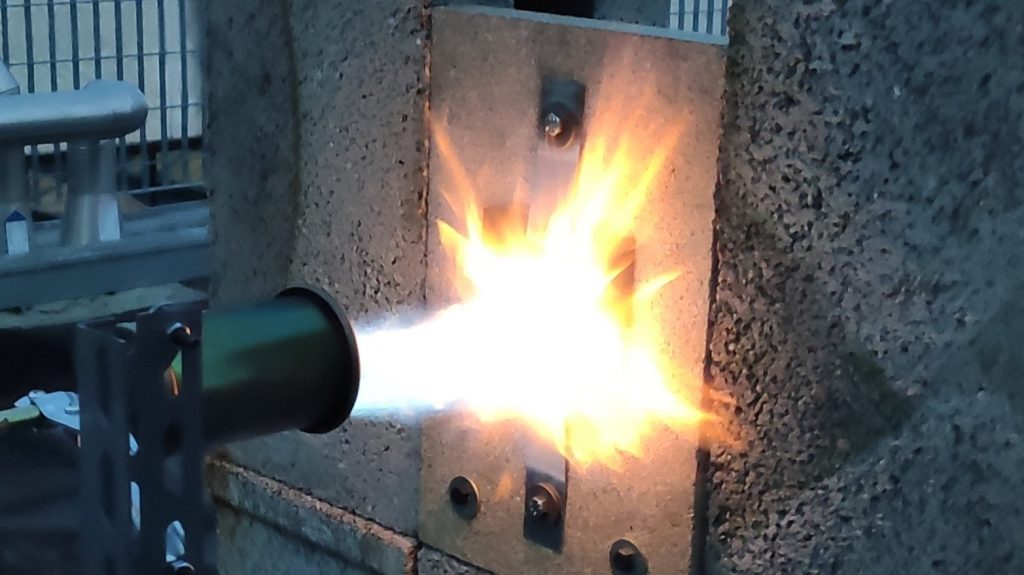

Fire resistance

Thermal insulation

Waterproof

Small to large production volumes

Tab to cell laser welding

Ohmic resistance

Reliability

Repeatability

Process automation

Process speed

Process safety

Measurement of 100% of the cell’s temperatures

Active safety

Process control

Life long diagnosis

Internal parts made by injection molding

High volumes

Quality

Passive safety

Disassembly

Reuse

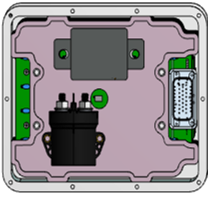

On-module control and protection

Manufacturing safety

Installation safety

Service safety

Post-crash safety

Module direct reuse

Wiring harness free

Quality

Reliability

Manufacturing

Disassembly

Reuse

Thermal conditioning

Manufacturing

Reliability

Versatility

Disassembly

Reuse

Cloud computing

AI

Active safety

Service support

E-cert

Asset management

Reuse